What types of innovations does Geographe focus on?

We focus on Enhanced Performance Parts and Specialised Tooling to improve mining maintenance efficiency and reduce operational risk.

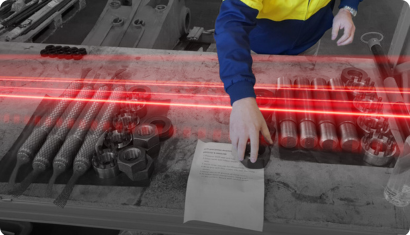

By listening to our clients and analysing their outcomes with OEM parts, our team uses cutting-edge technology to enhance parts and support miners with their maintenance and safety challenges.