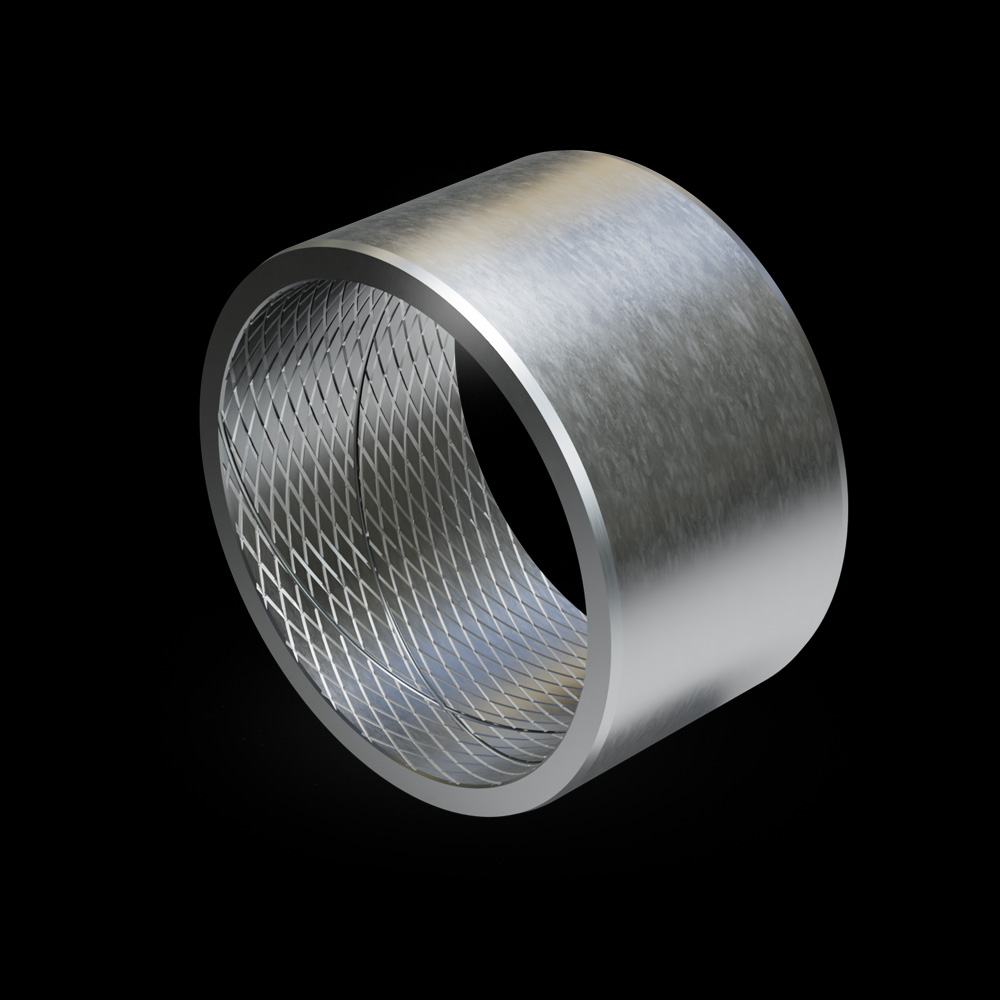

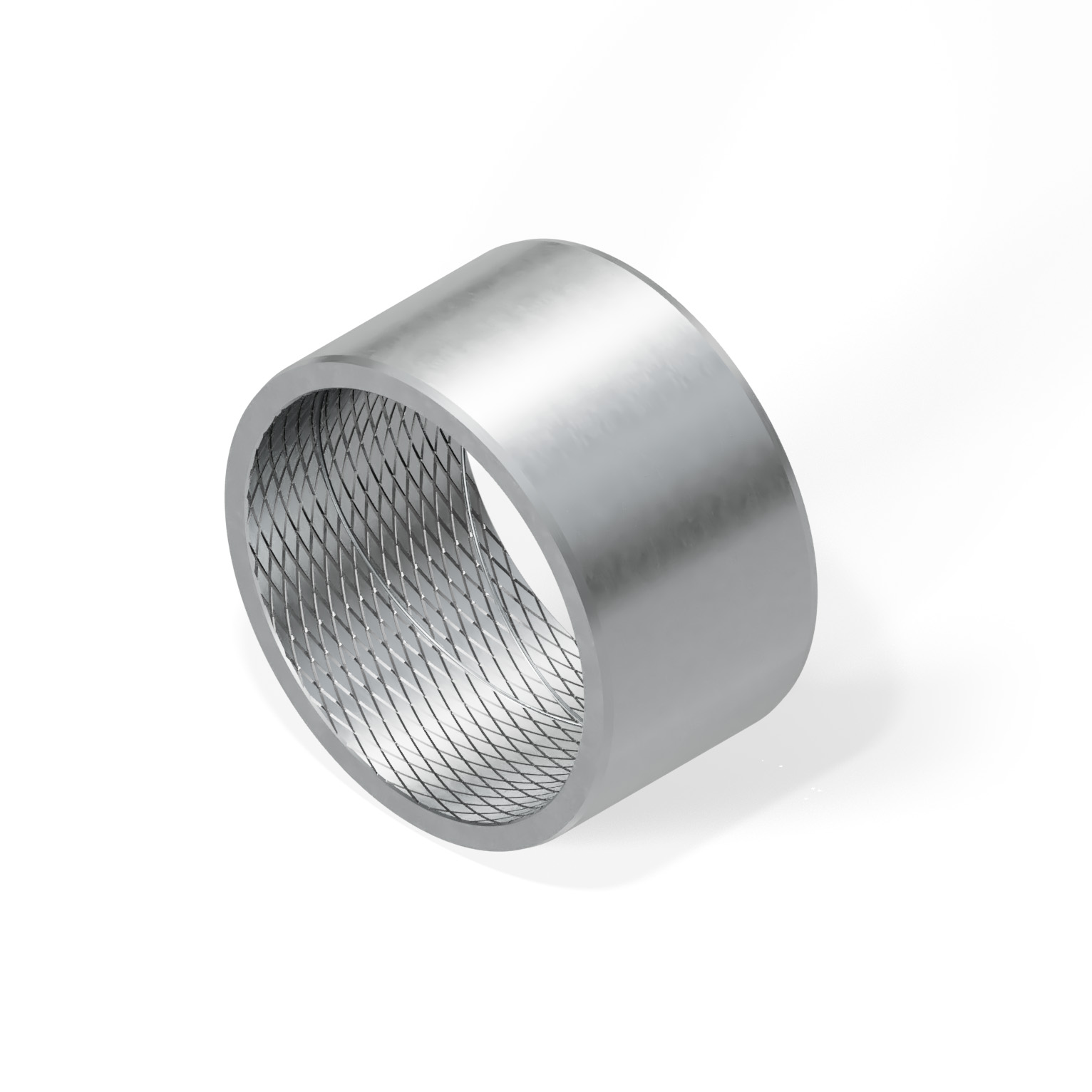

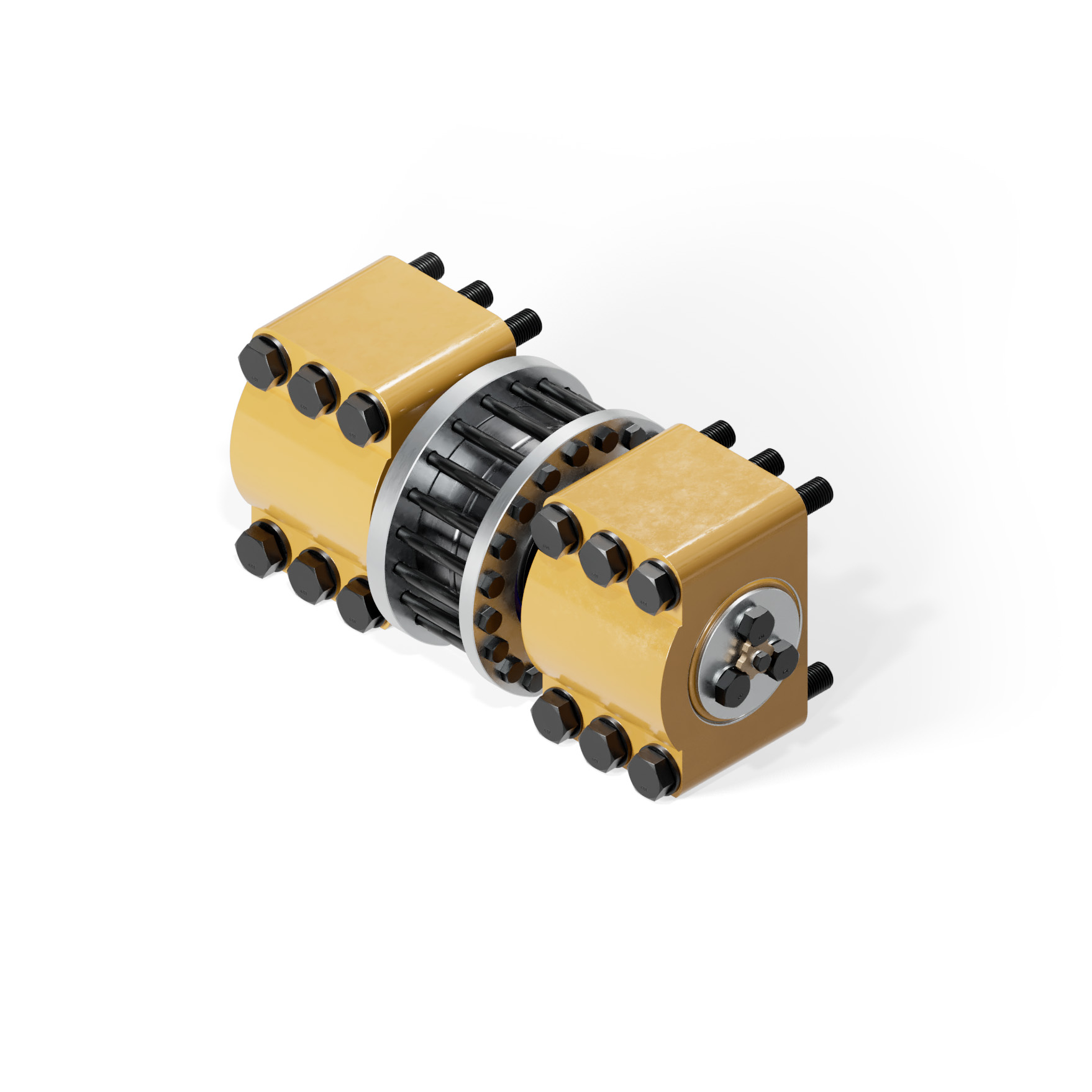

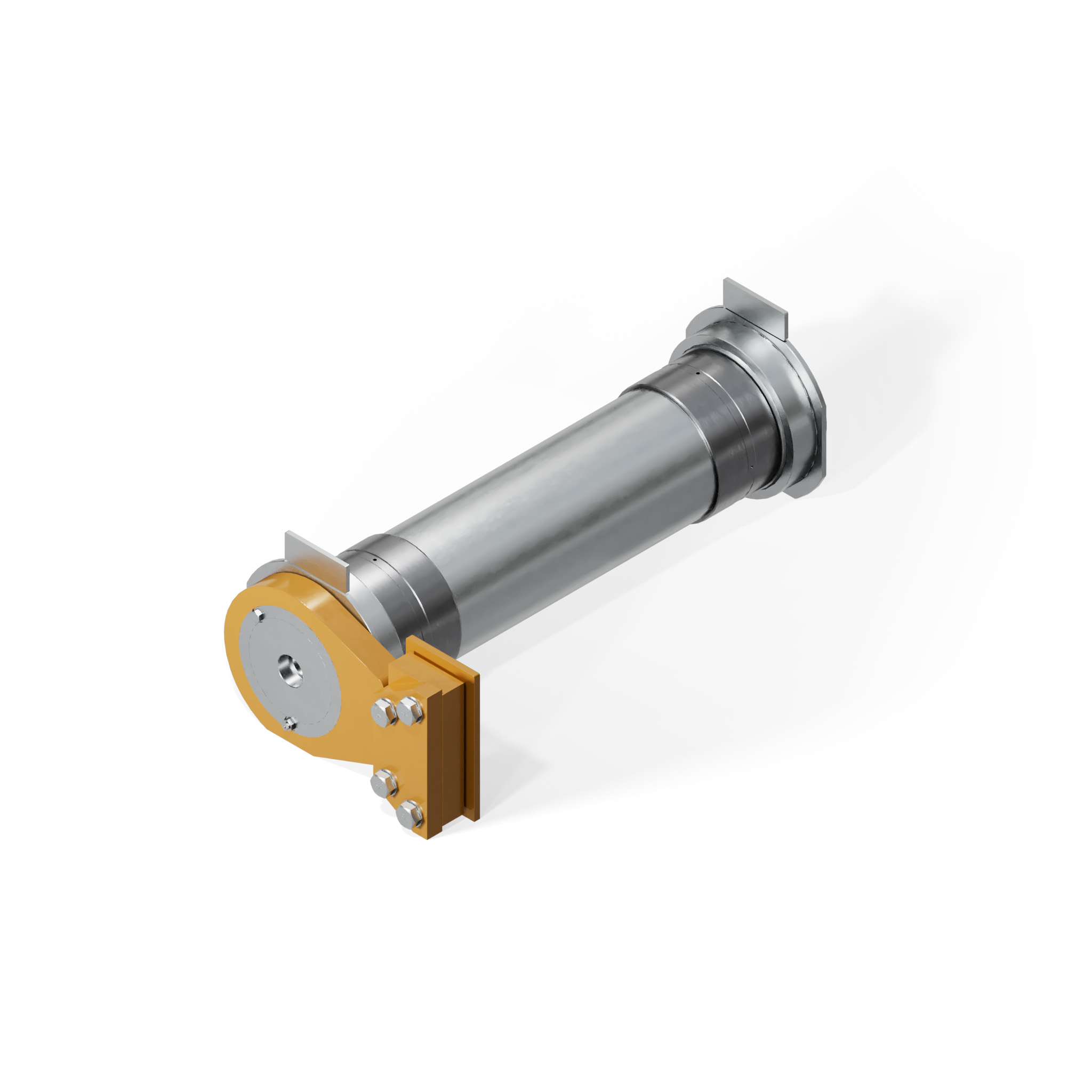

What are Enhanced Performance Parts?

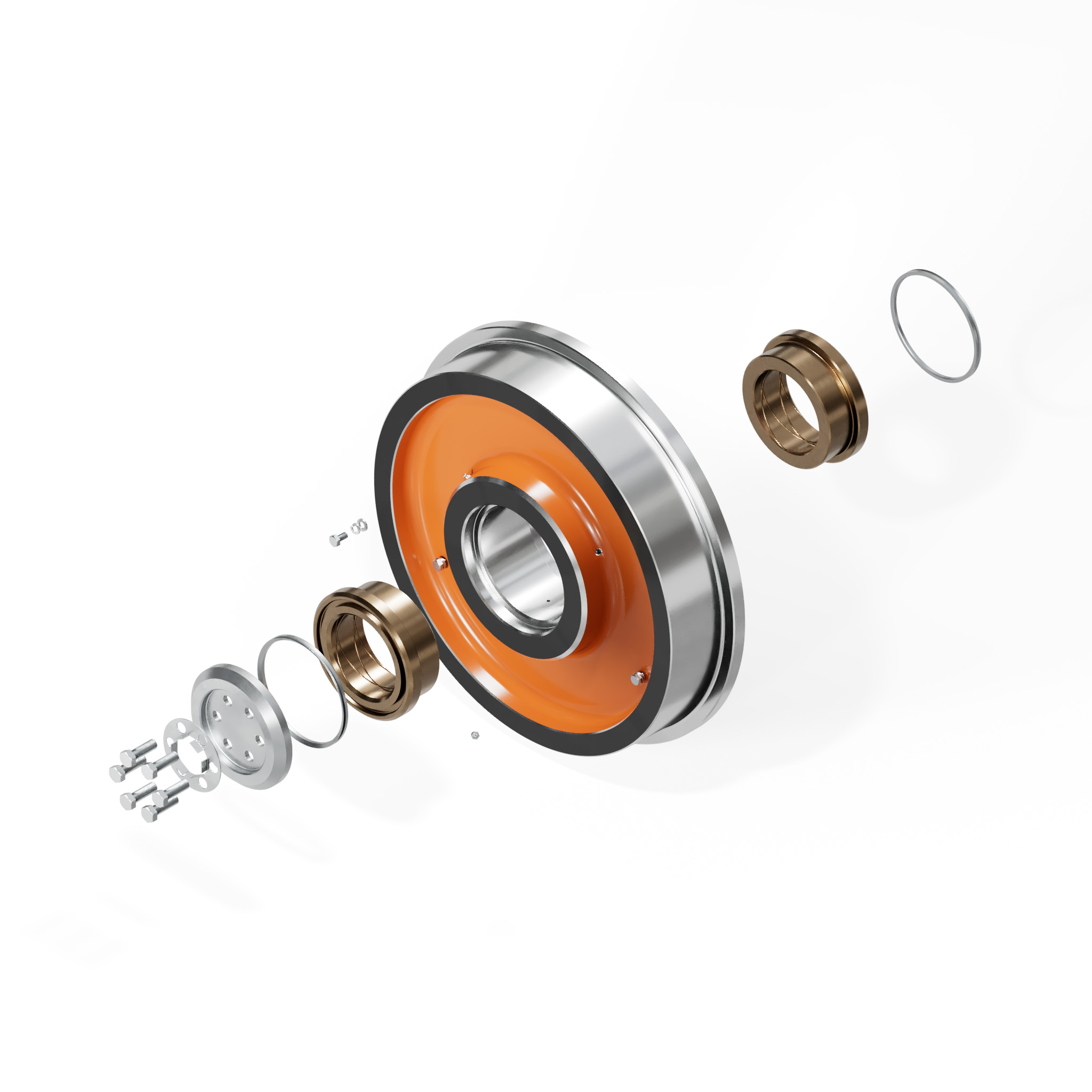

Enhanced Performance (EP) parts are specifically engineered to solve common challenges mine sites face, optimising the performance, durability, and efficiency of machinery used in mining operations. Enhanced Performance parts incorporate advanced materials, innovative designs, and rigorous testing by enhancing the current design, offering superior resistance to wear, corrosion, and impact, resulting in extended service life and reduced downtime to achieve operational excellence.

.png)

-1.png)