THE AUSTRALIAN WAY

True to the Australian spirit of reliability and hard work, our service ethics are built around understanding and meeting the needs of Australian miners and off-site repairers. We pride ourselves on a straightforward approach to business, valuing honest communication, strong partnerships, and performance solutions.

By aligning our operations with the tough, resilient character of the Australian mining industry, we guarantee not just satisfaction but a true competitive advantage for our customers.

Our Australian Operations

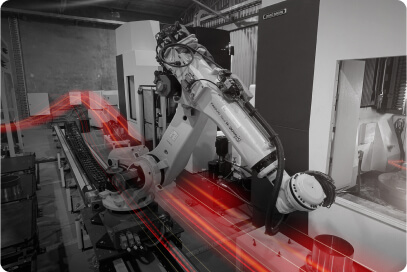

In an industry where a minor delay can cost millions, you can sleep soundly knowing Geographe’s vertically integrated, precision manufacturing base and advanced robotics are designed to deliver industry-leading manufacturing times. You're welcome to visit our Bunbury manufacturing facility to experience first-hand our approach to solving mine site challenges.

Enhanced Performance Solutions for OEM Mining Machines

Innovation, Design & State of the Art Manufacturing

Fixed Plant Enhancements

& Repairs

Our local presence and supply chain mean fast turnaround to your site

We pride ourselves on our strong local presence across Australia. Our strategically located distribution facilities and offices ensure we are close to key mining sites, enabling us to respond swiftly to the unique demands of our customers.

Our local presence not only fosters strong relationships through regular, personal interaction but also means we can offer hands-on, immediate support and service.

Western Australia

Perth, Kalgoorlie, and Bunbury

Queensland

Bowen Basin, Townsville and Mackay

New South Wales & Victoria

Hunter Valley and VIC Region

Meet our Australian team

As a third generation privately-owned company, our culture is steeped in the understanding that people matter to us. We care about individual development, sense of value within the company and encourage transparency in communication.

Whether it's with technology and its application in our manufacturing centres, or strategies on how to navigate customers' needs in challenging mine site situations, there are Geographe professionals in our team whose service and dedication to developing products, sales and manufacturing have spanned decades.

.jpg?width=733&height=642&name=engineered%20solutions%201%20(2).jpg)

Request a site visit

Our team regularly visit mine sites to discuss the challenges our customers have with their mining equipment on site; and to offer solutions designed to keep equipment running longer.

Complete the form and one of our team will be in touch to arrange a site visit with you.

Ready to take the next step?

Upload your details now and let your journey with Geographe begin.

“The Caterpillar Haul Truck Ball Stud Removal Tool has reduced the time to remove ball studs from 12 hours per truck to just 1 hour. The risk of damaging jacks throughout the process has also been removed. This initiative represents a significant cost and time reduction while also improving safety for our maintainers.”

- Truck Maintenance Superintendent FMG Fortescue Metals Group

“The construction and design of the Geographe Top Hat bush means we never need to repair the stick face again. This has resulted in a better maintenance practice for our site.”

- HME Supervisor

Rio Tinto Pilbara Iron

Australian News and Projects

FEATURED

The Role of Enhanced Performance Parts in Safer Mining Equipment Maintenance

Mining equipment maintenance has long been a challenge due to the demanding conditions and heavy workloads that accelerate wear and tear. While traditional methods such as thermal lancing have been effective, they come with significant risks. However, the emergence of Enhanced Performance (EP) Parts it offers a safer and more efficient solution for maintenance practices.

FEATURED

The High Demand for Quality Wear Parts

Geographe supports mining customers by optimising their mobile fleet to minimise operational costs through Geographe Enhanced Performance™ (EP) parts and solutions. Geographe’s EP parts have also been instrumental in preventing premature equipment failure in North-East Asia, particularly the top hat bush, a custom solution engineered to enhance the original product design and strength of the thrust plate and bush arrangement in Hitachi excavators.

FEATURED

Ball Stud Removal Tool Puts Geographe on the Map

After the Geographe team received a call from the workshop of a Tier 1 miner regarding a maintenance challenge on a common haul truck, the West Australian manufacturer turned a major safety issue into a patented, time-saving tool.

.png?width=759&height=960&name=AM%20December%202021%20cover%20(1).png)