MINIMAL ENVIRONMENTAL IMPACTS

Led by Sam Hyder, CEO, Geographe is a third-generation, privately-owned company excelling in enhancing mining fleet productivity, safety, and reliability. With 150+ passionate professionals in our team, we have a core productivity goal improvement (output per kW used) of 25% by 2025.

In 2005 we achieved the internationally recognised

Environmental Management System Standard: AS/NZS ISO 14001.

This SAI Global system ensures continuous improvement in the areas of.

Waste Minimisation

Prevention of Pollution

Energy Efficiency

Promotion of Recycling

As a trusted supplier to the mining industry, we recognise the importance of minimising our environmental impact and focus on areas including:

1. Recycling excellence

We've implemented a comprehensive recycling policy that ensures over 95% of the materials we use in our products are recyclable. From ferrous to non-ferrous materials, we prioritise recycling to reduce waste and promote circularity in our industry.

2. Supply Chain Accountability

While maintaining high-quality standards in our supply chain, we recognise the need to align with environmental best practices. We're actively working to integrate environmental criteria into our supplier assessments, ensuring that our partners uphold the same sustainability standards we do.

3. Solar Power Innovation

With a goal of our manufacturing plant using zero power from the local grid, Geographe is investing in solar power with the aim for our operation to run throughout the day with zero electricity usage by 2025. By harnessing the power of the sun, we aim to significantly reduce our reliance on traditional energy sources. We've taken steps to integrate renewable energy solutions, such as the recent installation of 100kW of solar panels at our Perth workshop. This has resulted in up to 50% reduction in our direct grid reliance. Our workshop transition to solar power has yielded positive environmental outcomes with an estimated reduction in our greenhouse gas emissions by approximately 1.85mt of CO2 equivalents per month. A bi-product of this is a reduction of our overall costs by x $0.55 per square meter. While technical constraints prevent us from feeding excess power back into the grid, we're exploring battery storage solutions to optimise energy utilisation.

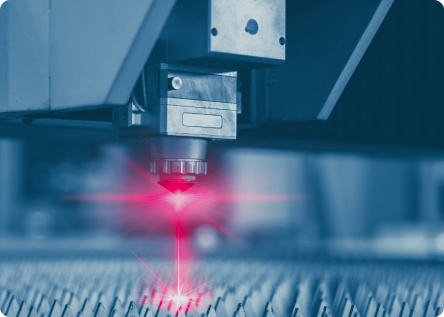

4. Cutting-Edge Efficiency

Our commitment to environmental sustainability extends to our machinery. The state-of-the-art equipment we’ve installed at our Bunbury factory from world class manufacturers including Dematic, DMG Mori, Okuma, and Modula offers unparalleled efficiency and productivity gains as a result of world first combinations and implementations. These installation advancements translate to substantial energy savings and improved performance.

5. Preferred Environmental Supplier

Our initiatives, from recycling practices to responsible hazardous material disposal, underscore our commitment to sustainable manufacturing. By prioritising environmental considerations, we're proud to offer mining customers a trusted supply chain which meets their criteria.