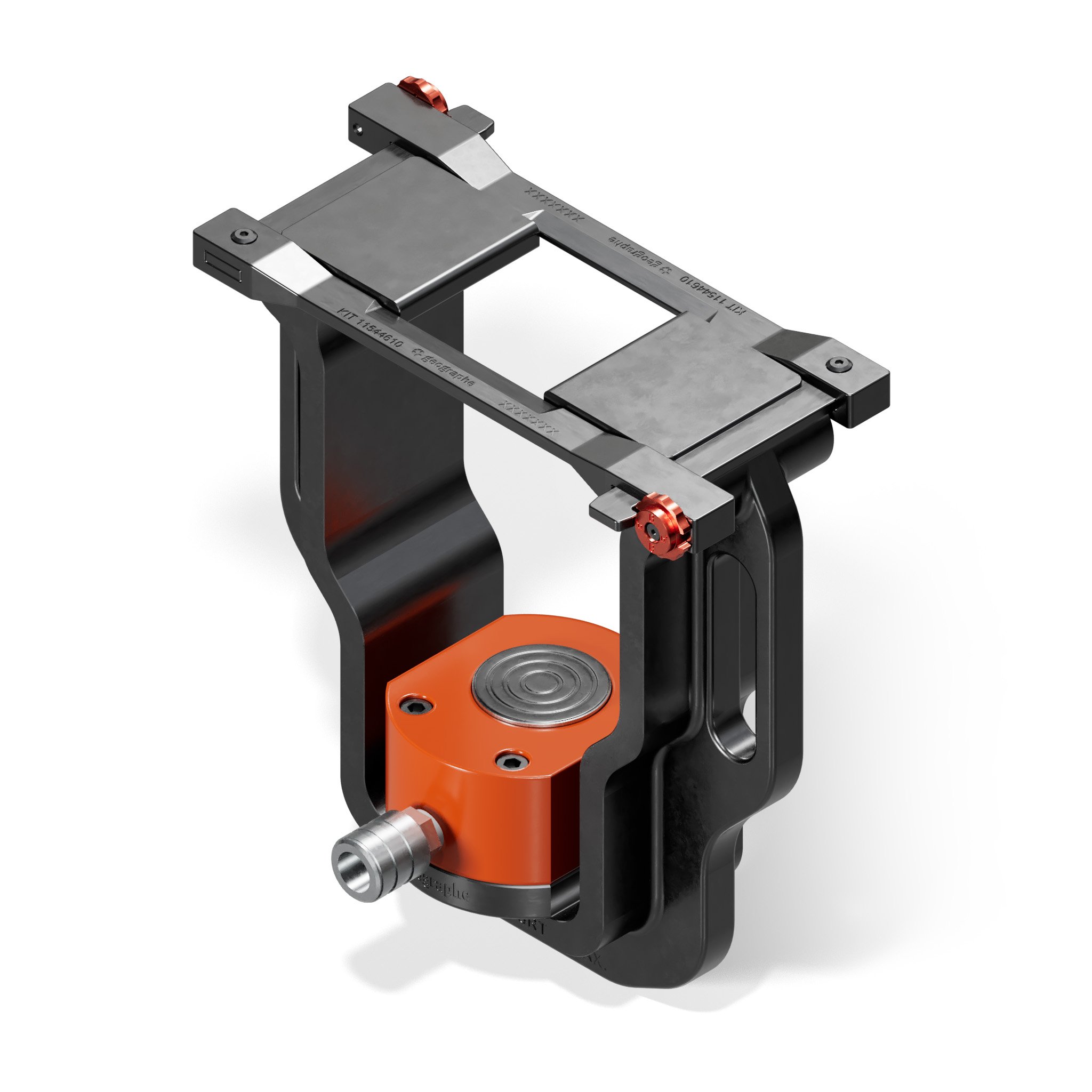

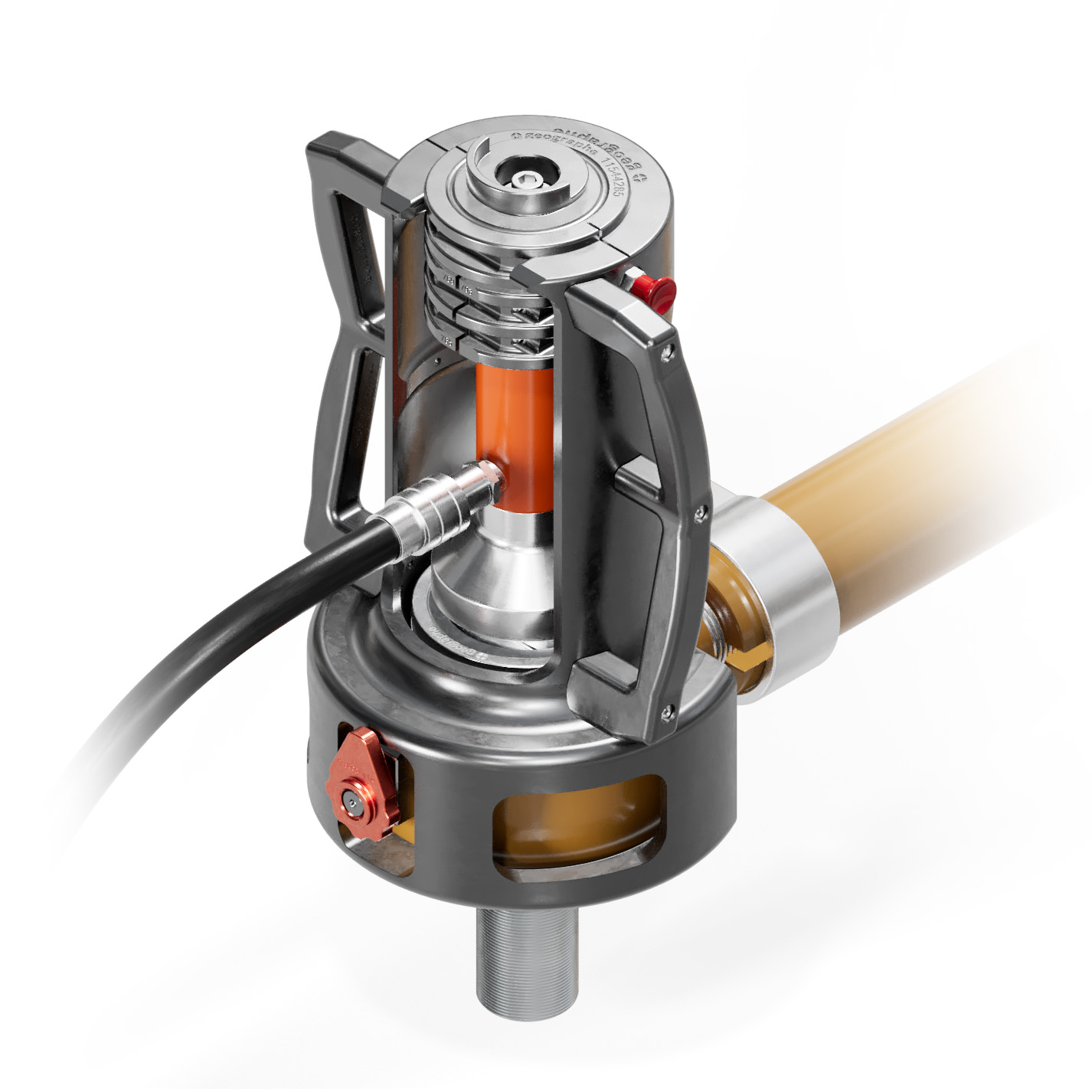

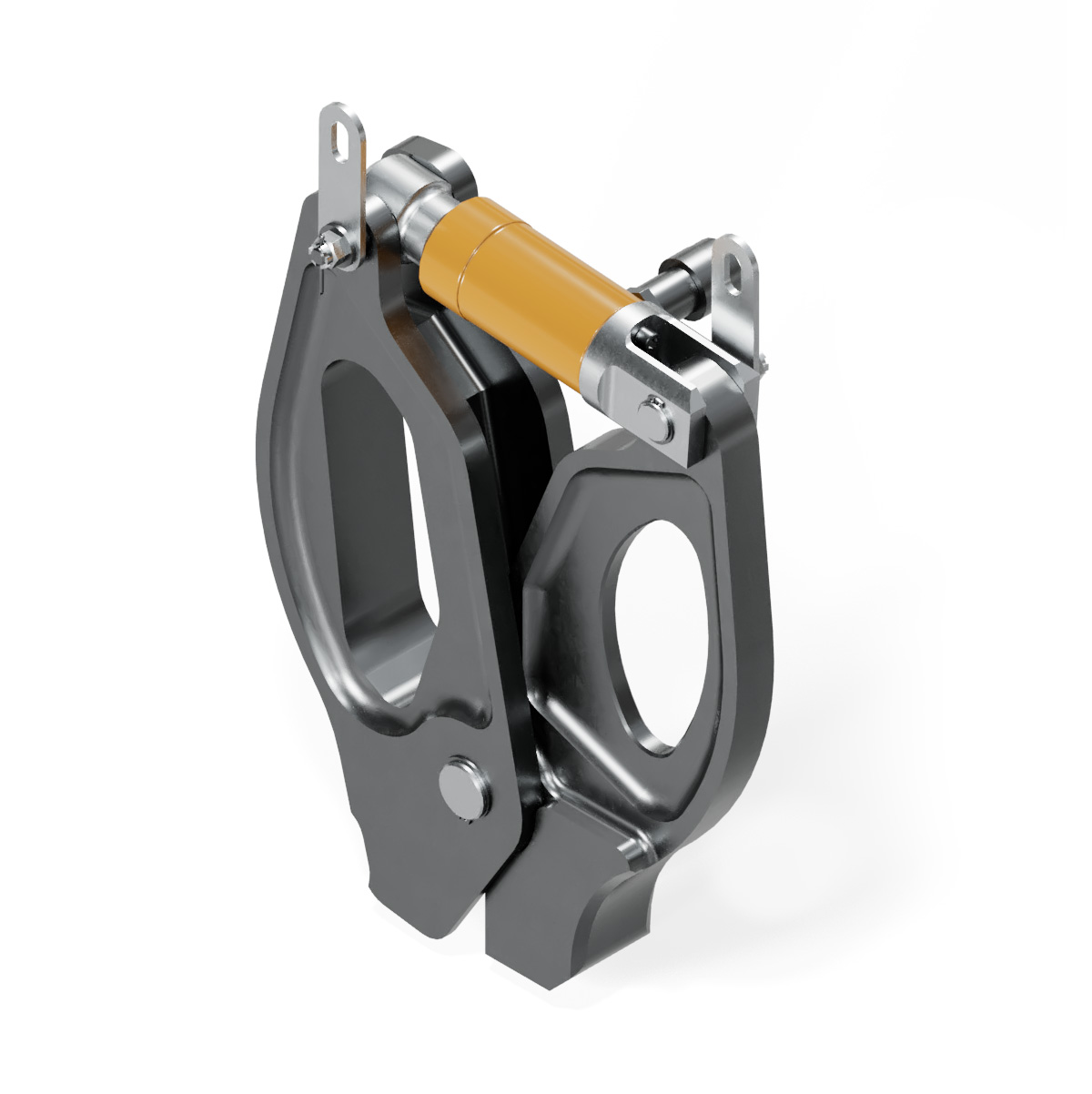

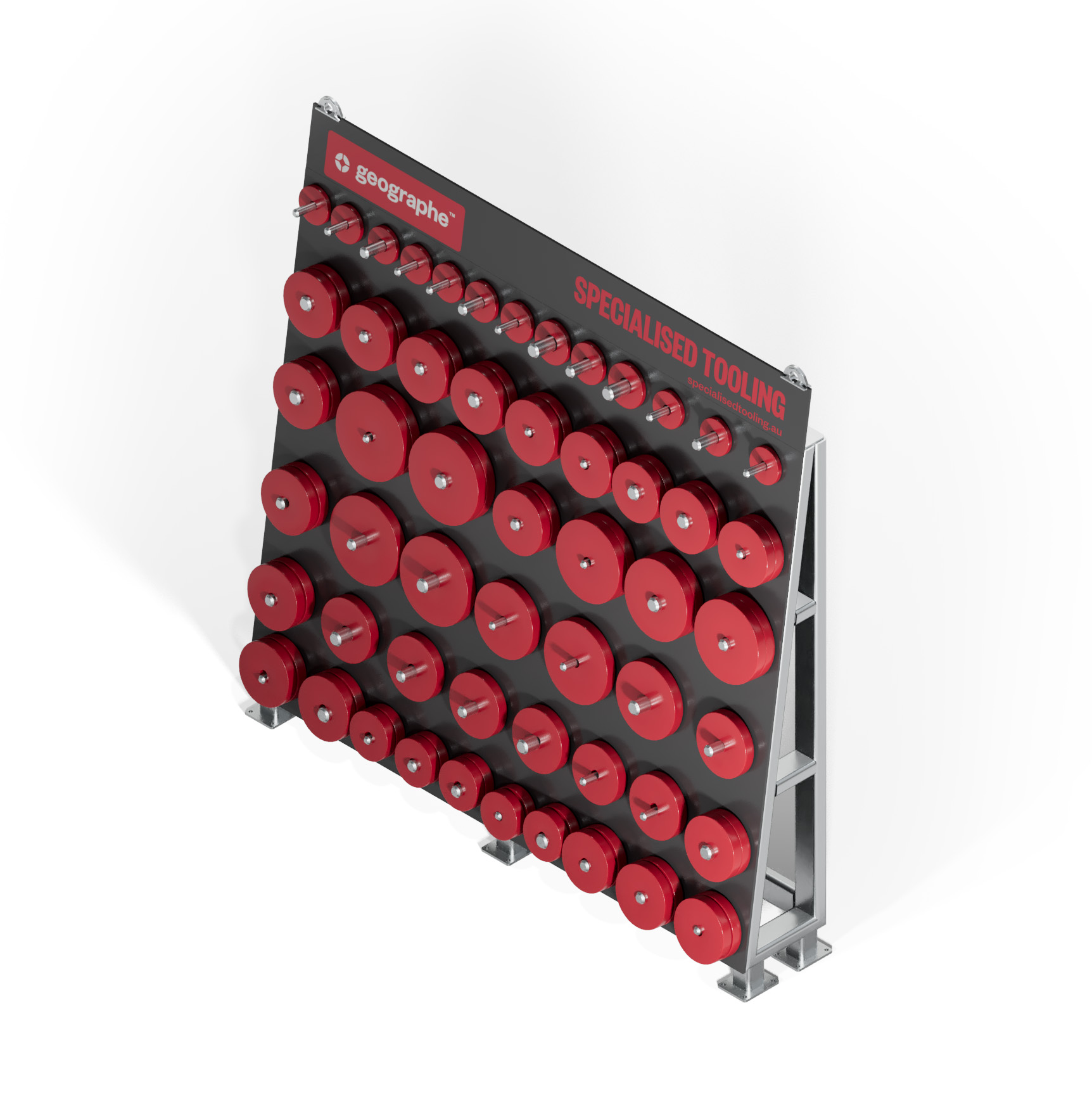

What is Specialised Tooling?

Specialised Tooling refers to the development and production of custom tools tailored to meet specific requirements in various industries. The Geographe engineering team design purpose-built tools that are precisely crafted to address unique challenges encountered during maintenance, repair, and other operational processes in the mining sector. These tools are engineered to optimise efficiency, accuracy, and safety, empowering professionals to carry out their tasks with effectiveness and confidence.

.png)

.png?width=496&height=721&name=engineered%20solutions%202%20(3).png)