Are you facing challenges with standard OEM oil-filled cartridge pins on your site? With the Geographe Solid Pin Kit and Lubrication Kit, you can overcome these limitations and boost your fleet’s reliability.

Feedback from across the industry has highlighted several challenges associated with standard OEM oil-filled cartridge pins in loader pivot applications, including:

-

Unpredictable service life, which can disrupt maintenance planning.

-

Internal damage at installation, caused by the high pressing forces (80 to 100 tonnes) required to seat the pin.

-

Premature wear, particularly when lengthy pre-start warm-up procedures aren’t followed.

-

Lubrication limitations in high-load, low-speed pivot joints, an application where oil isn’t always the most effective solution.

These issues can significantly impact uptime, drive up maintenance costs, and shorten the life of critical components.

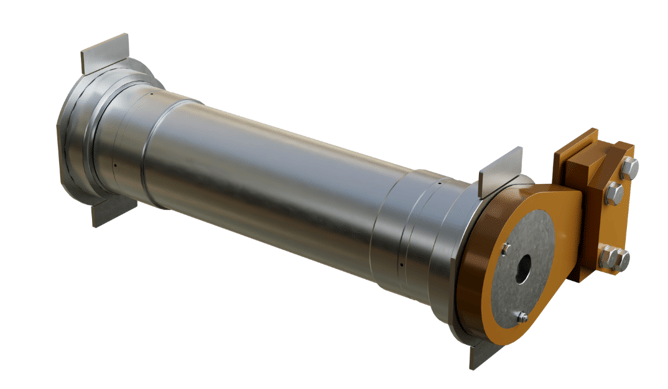

Geographe Greased Cartridge Solid Pins

To address these industry challenges, Geographe has developed the Enhanced Performance (EP) Greased Solid Pin Kits (SPK) designed for:

-

Easier, safer installation and removal

Our greased cartridge pins eliminate the need for 80–100T pressing forces, streamlining your assembly and dismantling process. -

Improved durability

Case-hardened bushings and pins provide superior wear resistance and extended service life. -

Engineered for better grease retention

Purpose-built bushings distribute and retain grease where it’s most effective. -

Contaminant control

Pressure-fed grease continuously purges contaminants, reducing internal wear and boosting performance. -

Optimised for loader pivots

Grease-based lubrication is ideal for high-load, low-speed applications, making this solution particularly well-suited to loader pivot joints. -

Reduced downtime

By addressing premature wear and limiting maintenance frequency, your machines can stay operational longer between service intervals.

Lubrication Kits

Geographe’s lubrication kits are specifically designed to work seamlessly with our Greased Solid Pin Kits (SPK), offering:

-

Automatic lubrication

The existing onboard grease system is leveraged to automatically lubricate each bushing, reducing manual maintenance and increasing efficiency. -

Custom fittings

For the CAT 992K Pin B, the kit includes custom Banjo Fittings that screw directly into the existing threaded holes on the top of the Boom Arm "legs," ensuring a secure fit without modification. -

Reduced risk of failures

Grease ports are strategically drilled and tapped into the Front Frame/Boom Arm, significantly lowering the risk of catastrophic failures caused by insufficient lubrication. -

Versatile attachment options

The kit offers two attachment methods to suit site preferences. It includes pot magnets, a magnet installation/removal tool handle, and stencils for safer, precise magnet placement. Alternatively, a Weld-on Boss option is available for those who prefer welding the components onto the boom. -

Exclusively compatible with SPK

Please note, that the lubrication kits are designed exclusively for use with Geographe Greased Solid Pin Kits and are not compatible with standard CAT oil-filled cartridge pins

A Partnership in Performance

You keep operations moving. We help keep your machines running.

At Geographe, we see our role as a supporting partner delivering cost-effective, reliable solutions that reduce downtime, improve component performance, and align with your fleet maintenance goals.

Let’s talk about how we can help extend component life and maximise machine availability!

Be abreast of Enhanced Performance Solutions for Mining Parts

How can we help?

Submit your details below and our team will contact you.