Improving the longevity of wheels at your site.

Built to withstand the toughest conditions

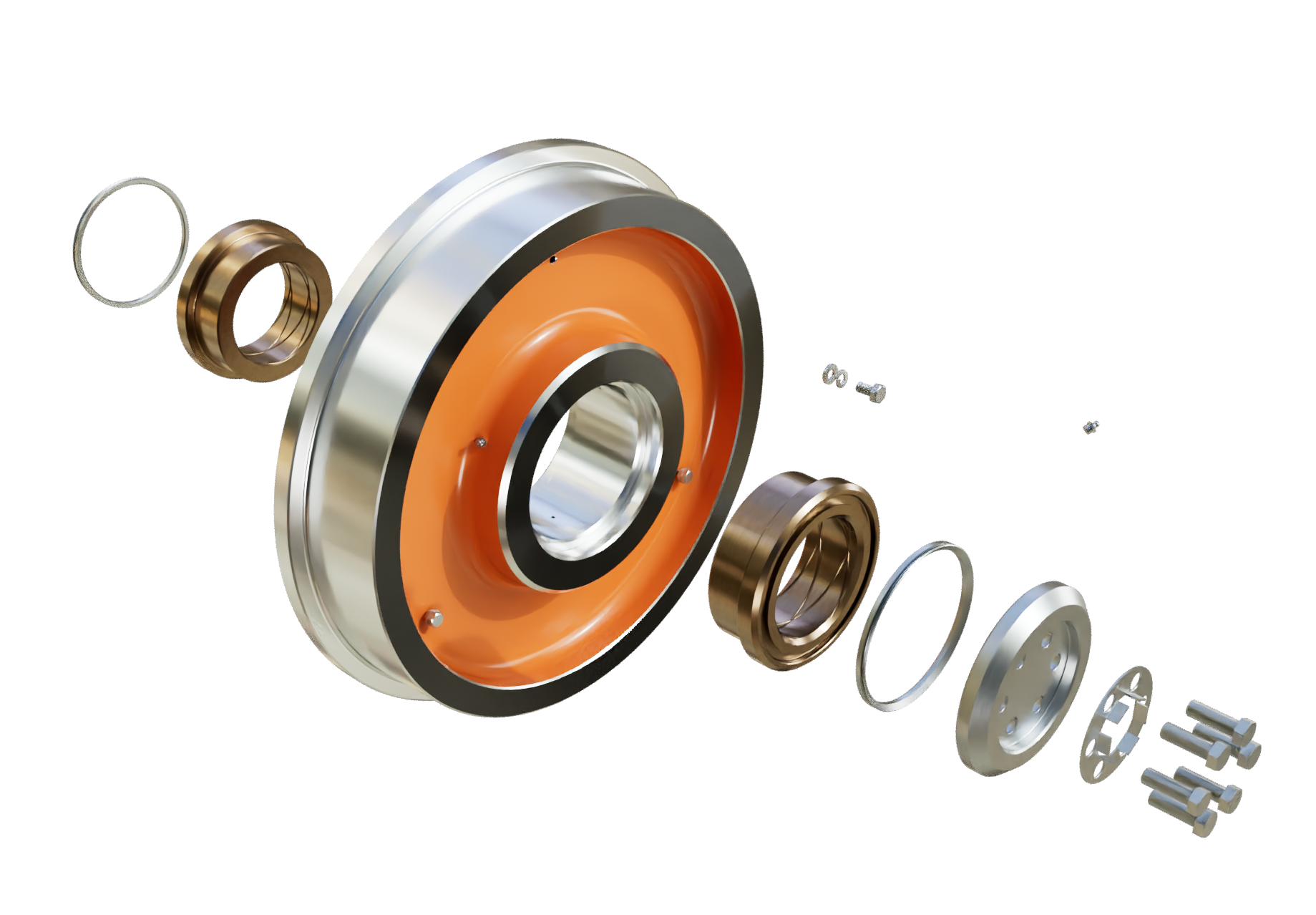

The Geographe Enhanced Performance™ (EP) Wheel is a high-strength, low-maintenance solution designed to outperform traditional cast wheels.

Manufactured in Western Australia, this assembly is ideal for heavy-duty applications where structural integrity, wear resistance, and operational efficiency are critical.

The Challenge:

Standard Cast Wheels are prone to failure

A Western Australian mining customer experienced costly replacements and unexpected maintenance interruptions from their OEM wheels. The cause was premature wear and structural failures stemming from common defects in poorly manufactured castings. This leads to significant operational problems, including:

- Increased Maintenance Costs

Frequent replacements and labour-intensive repairs drain your maintenance budget. - Unplanned Downtime

A single wheel failure can halt an entire production line, leading to massive productivity losses. - Safety Risks

Catastrophic failure of a load-bearing wheel can create hazardous working conditions for personnel. - Damage to Infrastructure

Worn or failed wheels can cause significant damage to expensive rail lines and surrounding equipment.

The Solution:

Geographe Forged Wheels

Our Enhanced Performance (EP) Wheels are engineered to eliminate common OEM failures. We use superior materials and processes to deliver a stronger, longer-lasting wheel.

- Reduce Costs

Cut maintenance expenses and eliminate middleman markups. - Increase Uptime

Extend part life with designs that correct OEM flaws. - Guaranteed Quality

Receive full transparency on production standards and quality control. - Expert Support

Our engineers provide expert guidance for your specific needs.

Industrial Wheels To Suit Your Mining Critical Assets

Geographe engineer application-specific solutions for your site's highest-wear points.

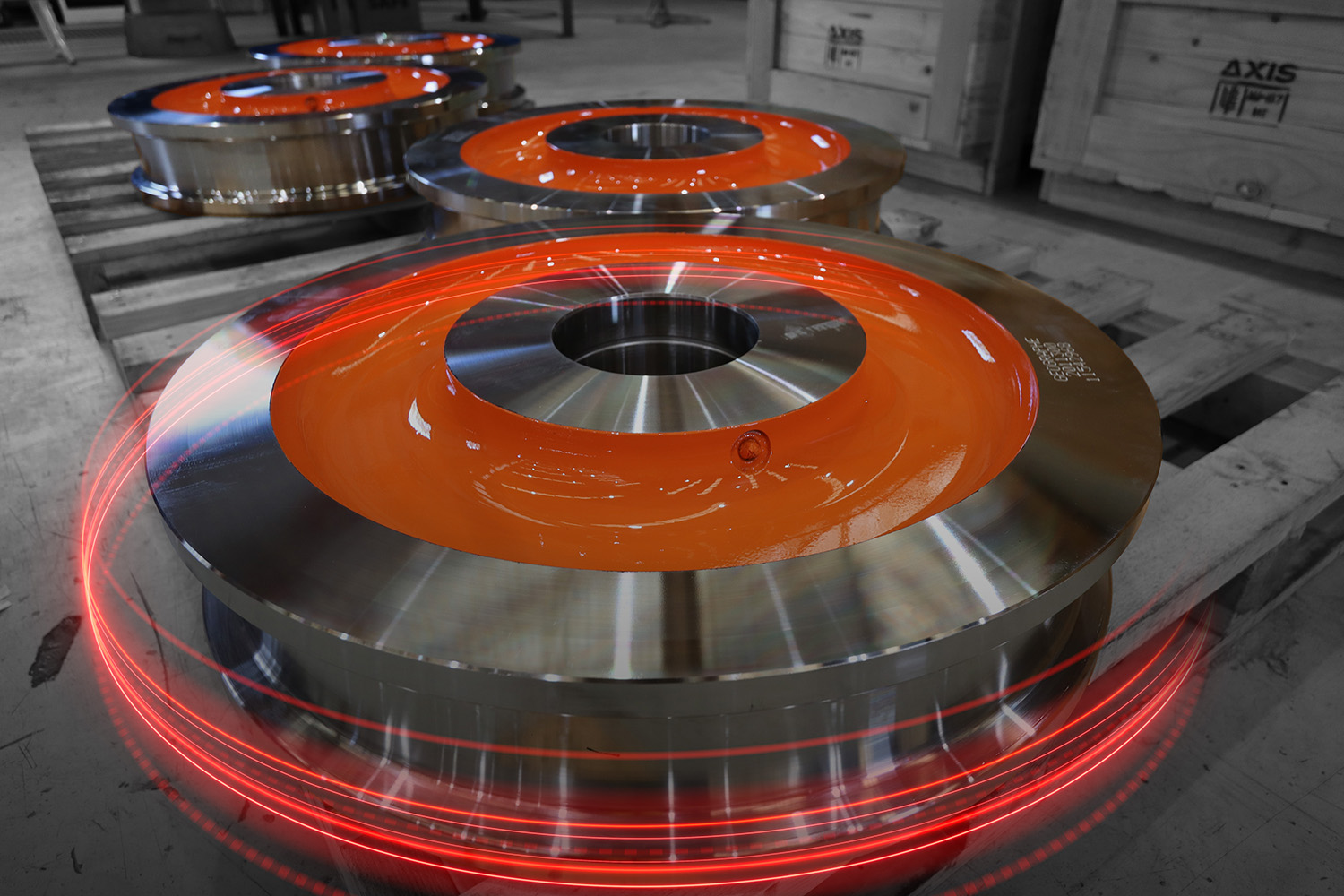

Stacker & Reclaimer Bogie Wheels

The Operational Bottleneck

As the undercarriage for enormous stacker and reclaimer machines, these wheels travel along rails to manage stockpiles. They must endure immense loads and harsh conditions, where standard OEM wheels often suffer from premature wear and structural failure.

The Engineered Advantage

Offering an improvement on longevity and wear over the OEM equivalent wheel, Geographe utilise a case hardening process to create a hard, wear-resistant surface with a flexible core. This leads to longer wheel life with less maintenance requirements.

Rotary Car Dumper Trunnions

The Performance Constraint

Trunnions act as the core pivot for a rotary dumper, supporting the entire weight of the dumper and a loaded rail car during the unloading cycle. This immense and repeated stress causes cracking and failure in inferior cast components.

The Technical Edge

By replacing castings with advanced forgings (offering up to 37% greater fatigue strength), our solution prevents premature failure and preserves structural integrity, ensuring safe and consistent unloading cycles.

Conveyor & Shuttle Wheels

The Maintenance Challenge

These wheels allow the shuttle head on a conveyor or ship loader to move back and forth for precise material distribution. Constant movement in highly abrasive, dusty environments causes rapid wear, impacting the accuracy and reliability of loading systems.

The Engineered Solution

Being a key operational component, these short travel wheels require constant wear monitoring.

Geographe’s aftermarket conveyor and shuttle wheels offer greater wear resistance while maintaining rail integrity. This is achieved by utilising a deeper hardened running surface in place of a much harder surface that could prematurely wear out the rails they operate on.

Our full contour hardening process achieves a uniform case hardness for superior wear resistance guaranteeing long-term performance and accuracy.

Idler & Drive Wheels

The Wear Point

Idlers and drive wheels are primary wear components in undercarriage and conveyor systems, subjected to constant abrasion and immense loads. Standard components wear quickly, leading to track/belt misalignment, bearing failure, and costly, production-halting downtime.

The Design Advantage

Our wheels feature advanced induction hardening for a deep, highly wear-resistant tread, combined with superior sealing to protect internal components from contamination. This extends the life of the entire system, ensuring reliable operation and reducing the frequency of costly undercarriage and conveyor maintenance.

How can Geographe Heavy Rolling Wheels optimise your maintenance operations?

Reduce Costs

✅ Stock held for contracted customers: Made in advance to reduce downtime

✅ Faster lead times: As well as reduced downtime with prioritised stock orders

✅ Lower maintenance and labour costs: by preventing premature wheel failures

✅ Competitive pricing: No middleman markups

Superior Strength

✅ Increased Strength: Up to 26% stronger and 37% more fatigue-resistant than cast

✅Reduced failure: through heat treatment, bead blasting, and CNC finishing

✅Full Wheel Customisation: To suit your needs, including material, size, and hardness

✅ Transparent quality control: Providing confidence in product reliability.

Let us know what issues you are currently facing with your existing wheels.

We can work with you to deliver a cost-effective, high-performance solution offering to supply full assemblies for rotable spares including bearings, shafts, sleeves and much more.

Complete the form below, and our team will be in touch.