STRIK

Steering Taper Repair and Inspection Kit

To suit Caterpillar 789 and 793 Haul Trucks

The engineered system for safe, precise, and in-situ steering taper reclamation.

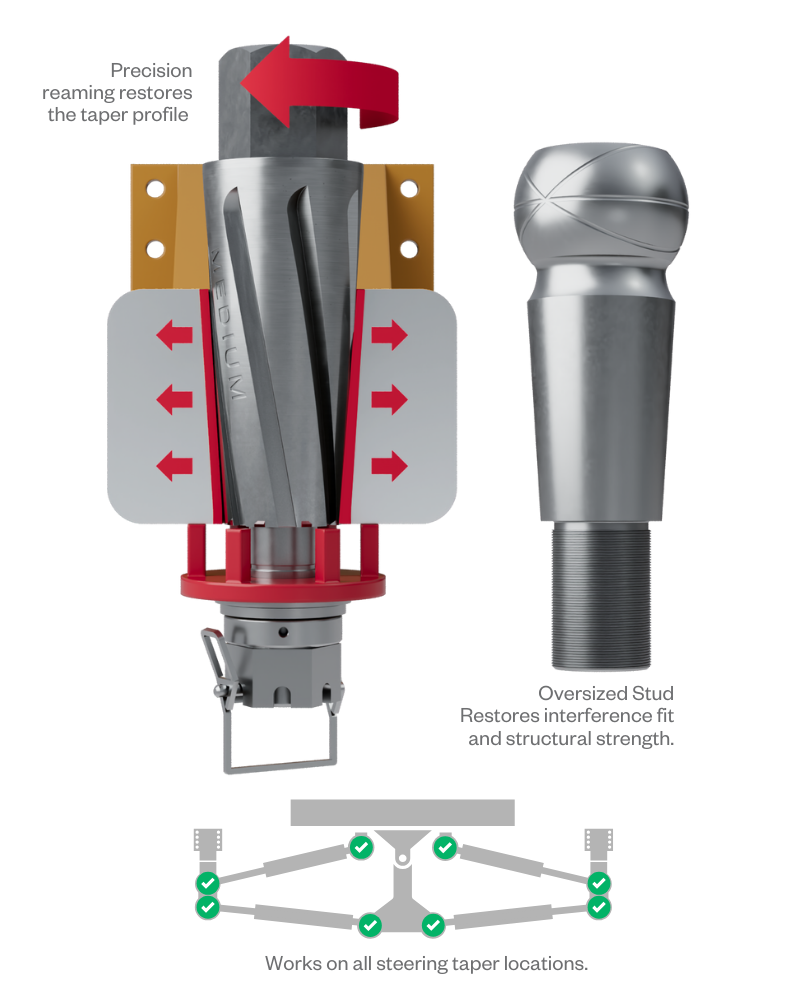

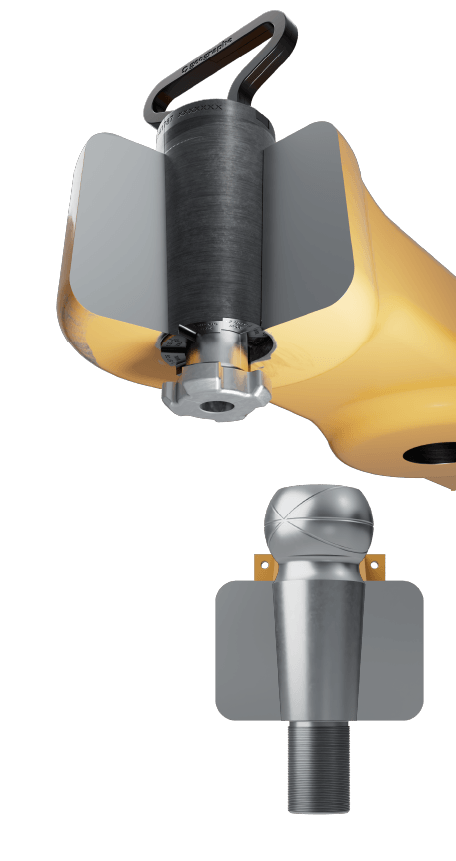

Developed with mine site maintenance crews, Geographe’s Steering Taper Repair & Inspection Kit (STRIK) validates and restores steering component tapers on Caterpillar 789 and 793 haul trucks. This purpose-built system replaces guesswork with engineering precision, allowing you to inspect wear, recondition damaged bores, and install oversized ball studs entirely in-situ. It guarantees a perfect interference fit, preventing catastrophic failures and extending asset life.

Maximise the life of parts

Standardised Proceedure.

No Guesswork

Hidden bore wear leads to ball stud movement.

Poor fitment causes stress concentrations and cracking.

Catastrophic failure resulting from a snapped ball stud.

The Challenge:

The hidden hazard in your steering system.

Steering components on haul trucks endure extreme loads and abrasive conditions. Over time, the tapered bores in the steering arm and tie rods become ovalized, pitted, or worn. Installing a new ball stud into a worn bore creates a critical safety risk because it leads to poor surface contact and stress concentration. This can cause the studs to crack, snap or come loose.

-

CATASTROPHIC RISK

A ball stud failure due to a loose taper fit can result in the total loss of vehicle steering control, posing a severe threat to operator safety. -

WASTED ASSETS

Traditionally, a worn bore meant scrapping the entire steering arm or sending it off-site for expensive, time-consuming machining. -

CRACKED BALL STUDS

OEM ball studs are reported to frequently crack and snap due to poor fitment in worn tapers, necessitating frequent replacements and increasing the risk of catastrophic failure.

The Solution:

Swap your old mate for a standardised procedure.

The STRIK replaces visual guesswork with an engineered procedure. This comprehensive kit allows technicians to validate the contact area using engineering blue, measure the wear, and precision-ream the bore to factory specifications, all while the truck is still on the stand or in the bay.

-

STRONGER THAN SLEEVING

Unlike sleeving repairs, which require removing significant material from the housing wall, the STRIK removes only the minimum necessary material to restore the taper profile. This maintains the structural integrity of the steering arm. - SUPERIOR STRENGTH

By fitting a Geographe Oversized Ball Stud, you are installing a component with a larger cross-section than the OEM standard, resulting in a stronger, more robust assembly. - IN-SITU RESTORATION

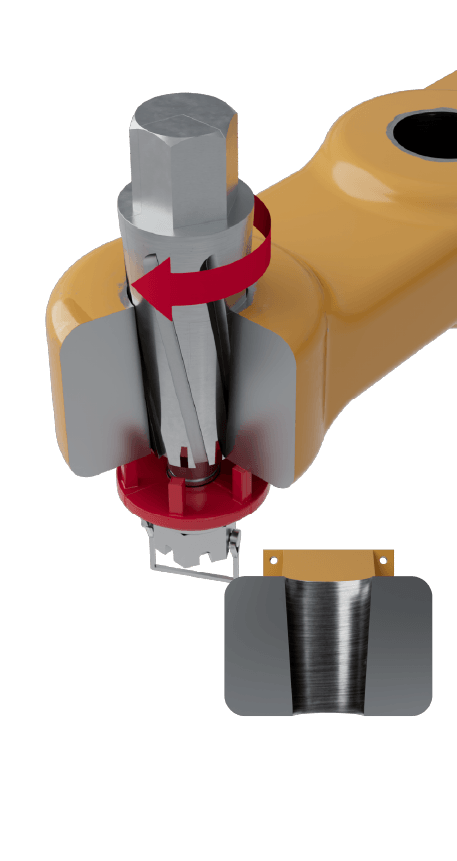

Precision reamers (Coarse and Medium) allow you to cut the bore to the next oversize (up to 3rd oversize) by hand or low-RPM drive, right on the truck.

How does it work:

4 steps for efficient taper reaming

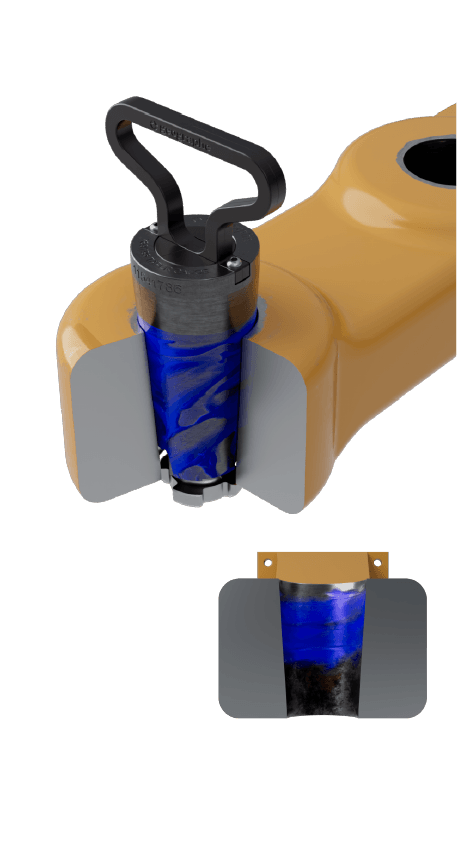

Assess, Gauge & Measure

Use the Taper Gauge and Bearing Blue to check surface contact and determine if the bore requires reaming to an oversize.

Ream & Restore

If wear is detected, use the Coarse and Medium Reamers to precision-cut the bore to the correct Oversize profile.

Inspect & Lap

Apply lapping paste and rotate the Lapping Tool to clean the bore and reveal the true surface condition.

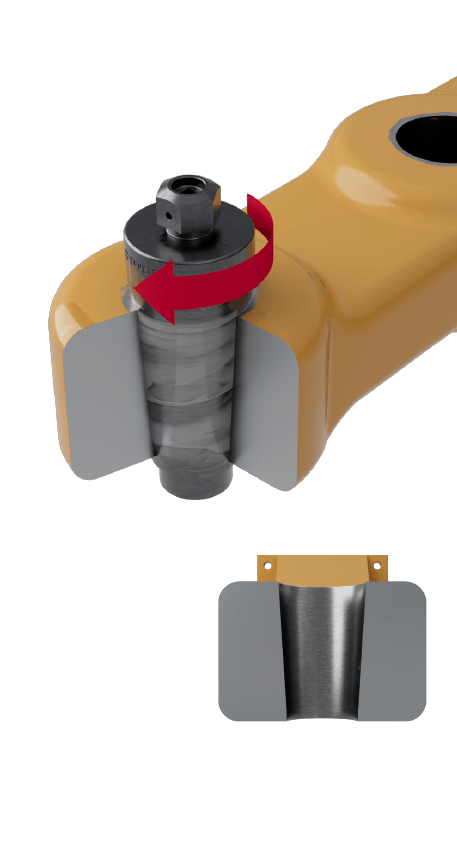

Verify & Install

Perform a final check with the Taper Gauge to confirm >75% contact area before safely installing the new Ball Stud.

Don't replace the part. Restore the fit.

The STRIK is more than a repair kit, it’s a lifecycle extension strategy for your fleet. In the field, maintenance teams often face the choice of fitting a standard stud into a marginal bore (risking failure) or scrapping the arm (wasting money). The STRIK provides a third, smarter option.

Recondition and Reuse

By standardising this inspection process, sites can prevent the common cycle of "change-out > loosen > fail," ensuring that every steering component leaves the bay with a factory-spec interference fit. This directly supports Zero Harm by eliminating the mechanical cause of steering loss events.

Flexible Single Person Operation

Maximise Crew Efficiency:

Instead of tying up multiple crew members on a single challenging task, the BSBIRT allows one operator to manage the entire process.

Guaranteed Consistency:

Geographe Specialised Tooling™ dictates the procedure. Our engineers and development team have done the hard yards, so you don’t have to. This removal of guesswork ensures the job is done to the same safe, high standard, every time.

Simplify Planning:

The BSBIRT can turn a high-risk, multi-person job into a straightforward, one-person task, making maintenance scheduling easier and the whole process more predictable and efficient.

Total Weight including waterproof wheeled case - 43kg

Total Dimensions of case - L 830mm / W 540mm / H 330mm

What's in the box?

The BSBIRT is a complete, engineered installation and removal system where every component is designed for a specific purpose:

Want to see the STRIK in action on your next bearing change out? We'd be happy to come and show you.

Register your interest below for the Steering Taper Repair & Inspection Kit (STRIK) to suit Caterpillar 789 & 793 haul trucks.

The STRIK is being produced in small batch numbers based on demand. If you are looking to make a safety or uptime improvement at your mine site or workshop, please add your contact details below and we'll be in touch regarding this Geographe Specialised Tooling™.