Safely and efficiently remove 785, 789 and 793 ball studs with Geographe’s patented product innovation.

Geographe have been supplying ball stud kits to suit Caterpillar 785, 789 and 793 trucks for many years and have now developed a tool to aid their removal.

How does it work?

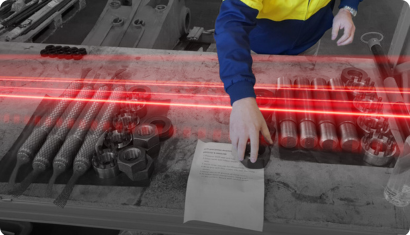

Geographe’s patented Ball Stud Removal Tool (BSRT) is a hydraulic pressing system designed to safely and efficiently remove ball studs from 785, 789 & 793 series haul trucks using pressure applied to the bottom or threaded end of the ball stud.

How does it perform?

In field testing, the BSRT has been removing studs at a significantly faster rate than the current industry norms. Success rates will vary however our customers have reported an average 90% success rate on removing studs on first attempt.

With a correctly positioned truck, and a crew of 6 working on the truck, 6 studs were successfully released in under 15 minutes during a test at a Western Australian Mine site in 2020.

Actual times will vary based on individual truck's condition and how they are set up for maintenance.

Is it easy to use?

One of the key qualities of Geographe’s BSRT is its ease and safety of use. It has been designed to be a single person operation tool and a full user manual is provided to help get the most from the tool.

Its general ease of use is summarised in 5 simple steps below:

- Undo the ball stud nut and back it off by two full turns

- Remove any excess grease on the top of the bell crank

- Simply slide on the tool which weighs only 19.5kgs

- Insert the hydraulic ram onto ram retaining points

- Fit the tool retaining bracket and pin and you’re ready to go.

Real-world removal scenarios will be different and considerations to be aware of include:

- Tie Rod to Bell Crank Gap – If the truck is not manipulated to allow the gap to be as parallel as possible the tool won’t fit. I.E. if tie rod is on too much of an angle.

- Tie Rod Adjustment Clamp – The clamps sometimes need to be released and moved back to allow the tool to be fitted.

- Steering Cylinder Type – Some larger diameter steering cylinders restrict fitment of the tool.

- Steering Position – Manipulating the steering/wheel angle can relax axial forces on the ball studs, assisting their release.

- Availability of 10,000 PSI Hydraulic Pressure – The tools hydraulic ram is reliant on this maximum pressure and we have discovered some sites do not have this ability.

A version to suit the 777 CAT Haul Trucks is available from January 2025. Please click here for more information.

Be abreast of Enhanced Performance Solutions for Mining Parts

Customer Testimonials:

“Developed with our contractor Geographe Engineering, the tool has reduced the time to remove ball studs from 12 hours per truck to just 1 hour. The risk of damaging jacks throughout the process has also been removed. By limiting the movement of the truck and the chance of hardened mud hitting the maintainer during the stud removal process, safety has been significantly improved. This initiative represents a significant cost and time reduction while also improving safety for our maintainers.” – Truck Maintenance Superintendent- FMG Fortescue Metals Group

“Feedback from the workshop team is the 9 out of 10 times the Geographe tool works fine. If they get a stubborn one they remove the tooling and apply heat to the steering arm, then refit the tooling and they usually pop.” – Workshop Supervisor – FMG Fortescue Metals Group

“Mate just some feedback on the uprated ball stud tool, we are very pleased with the upgraded tool performance. We are finding that it is working very well and haven’t found any yet that it hasn’t worked on, only one we had to apply a small amount of heat to the taper to make it pop.” – Maintenance Superintendent – Pilbara region mine site, Western Australia.

“Although we only have a relatively small 789 Fleet and no 793’s, I have seen this tooling at another company and know the value that it gives.” – Reliability Analyst, Mineral Resources.

“Using the Geographe Ball Stud Removal Tool, the workgroup was able to separate 6 ball studs in under 15 minutes, this all done without heat or excessive stress on steering components” – Mobile Maintenance Supervisor – South 32

“After using the Ball Stud Removal Tool, I have seen first hand the value it provides.” – Reliability Analyst, Pilbara region, Western Australia.

How can we help?

Submit your details below and our team will contact you.